Sodium-ion batteries (NIBs or SIBs) have emerged as a potential alternative to lithium-ion batteries (LIBs) due to the limited supply and high cost of lithium.

Key Takeaways

- Sodium-ion batteries are emerging as a promising alternative to lithium-ion batteries due to their lower cost, abundance, and potential for sustainability.

- Sodium-ion batteries have lower energy density and shorter cycle life than lithium-ion batteries, but they offer advantages such as fast charging, stability against temperature extremes, and safety against overheating or thermal runaway.

- The major challenges facing sodium-ion batteries include low energy density, incomplete industrial chains, and the need for innovative manufacturing and recycling methods.

- Major manufacturers, particularly in China and the United States, are investing in the development and commercialization of sodium-ion batteries. Companies such as CATL, BYD, Volkswagen-backed JAC Group, Northvolt, KPIT, and US start-up Peak Energy are making significant advancements and investments in this field.

- Sodium-ion batteries are not expected to replace lithium-ion batteries completely, but they have the potential to find a niche in specific applications and reduce lithium demand.

- The Center for Strain Optimization for Renewable Energy (STORE) at UCLA is working to improve sodium-ion batteries to where lithium is now within the next 10 years by developing materials that have big spaces in them so sodium can move without resistance, engineering layers that resist rearrangement by sodium, and making materials that are malleable and able to flex to accommodate volume change.

- The sodium-ion battery market is expected to grow by USD 414.4 million from 2023 to 2028, according to Technavio, with expanded applications in grid energy storage and electric vehicles fostering the sodium-ion battery market’s continual evolution.

Sodium-Ion Battery Advantages

A significant benefit of sodium-ion batteries is that sodium is abundant and less expensive than lithium. They can be a long-term option with lower battery pack costs and the ability for rapid application in current battery production plants.

In addition, sodium-ion batteries show potential for specific applications, such as material handling equipment.

Sodium-Ion Battery Challenges

While sodium-ion batteries have plenty of benefits, there continue to be certain drawbacks. Sodium-ion batteries are lacking in the energy density of lithium-ion batteries, which may limit their utility for some applications. Their reduced energy density may make them unsuitable for larger electric vehicles (EVs).

However, sodium-ion batteries could be employed in lower-end, shorter-range vehicles or in power-grid energy storage, where size is less important.

Sodium-Ion Battery Technology and Development

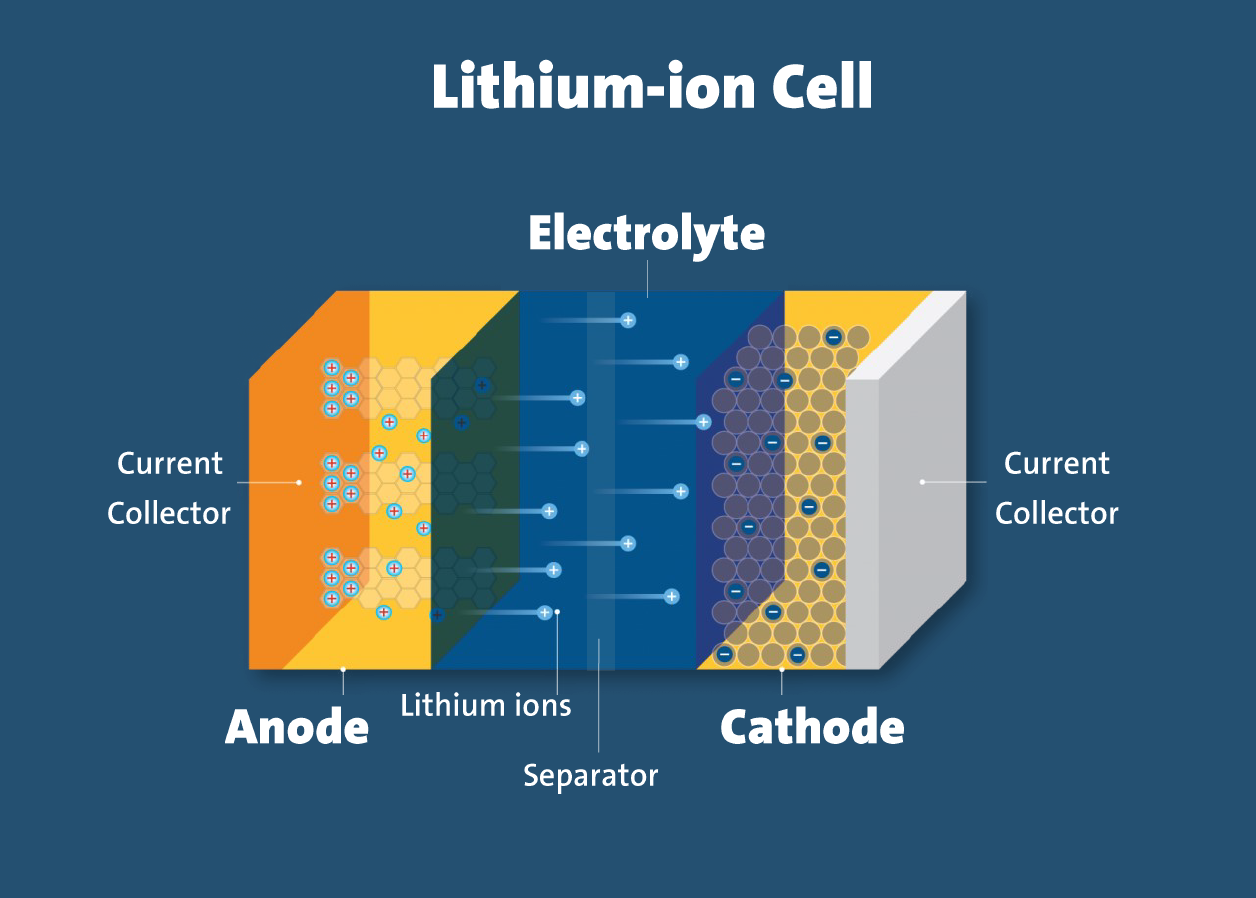

Sodium-ion battery technology has parallels with lithium-ion battery technology, such as the use of a cobalt-containing active component.

However, alternatives are being investigated to solve sustainability and economic problems. Cathodes based on sodium transition metal oxides have attracted a lot of interest due to their high tap density, operating potentials, and capacities. Research activities are aimed at reducing the cost of components like cobalt.

Anodes for sodium-ion batteries can be formed of hard carbon, graphite, tin, molybdenum disulfide, graphene, or carbon arsenide. Hard carbon provides a superb balance of capacity, low working potential, and cycle stability. Graphite, tin, and molybdenum disulfide have all been investigated, but their cycling stability and capacities have differed. Graphene Janus particles were employed to improve energy density. Carbon arsenide mono/bilayer has shown promise due to its high specific gravity, low expansion, and ultra-low diffusion barrier.

Industry Momentum and Commercialization

Major manufacturers are actively pursuing the development and commercialization of sodium-ion batteries, especially in China and the United States. Major manufacturers have already begun commercial production of sodium-ion batteries, specifically for use in electric vehicles.

Furthermore, the current lithium-ion battery manufacturing facilities can be repurposed for commercial sodium-ion battery production, providing an advantage in terms of infrastructure and scaleability.

The use of sodium-ion batteries could have a substantial impact on lithium use. Sodium-ion batteries have the potential to reduce lithium consumption, providing a solution to the existing supply limits and price volatility of lithium.

However, it is unclear if sodium-ion batteries will become widely available or remain a niche product in the battery industry.

Can Sodium-Ion Batteries Replace Lithium-Ion Batteries?

Sodium-ion batteries have significant benefits over lithium-ion batteries in terms of sodium availability and cost. These advantages make sodium-ion batteries a compelling option, especially given the scarcity and expensive cost of lithium.

Sodium-ion batteries also exhibit constraints for commercial applications. The decreased energy density of sodium-ion batteries compared to lithium-ion batteries may make them impractical for some uses, notably in bigger EV models.

However, sodium-ion batteries may find use in low-cost, tiny automobiles or two-wheelers that do not need a high energy density. They also demonstrate possibilities for power-grid energy storage, where cost and size are less important considerations.

Recent Big Bet on Sodium-Ion Batteries by Industry Giants

Several major companies have recently made significant investments and advancements in sodium-ion battery technology. This has further fueled the race for the widespread adoption of this technology.

For example, CATL, the world’s largest battery manufacturer, recently announced the start of mass production of sodium-ion batteries. Additionally, BYD, the world’s top electric vehicle (EV) maker, signed a deal to build a $1.4 billion sodium-ion battery plant. This signals its commitment to scaling capacity and commercializing this technology.

Other automakers, such as Volkswagen-backed JAC Group’s Yiwei, have already delivered the first sodium-ion battery-powered electric car.

Northvolt and India-based KPIT have also made significant breakthroughs in sodium-ion battery technology.

US start-up Peak Energy aims to roll out its sodium-ion batteries by 2025 and open a giga-scale manufacturing plant the following year. The company claims its sodium-ion battery technology is “safer” and “more reliable” than existing lithium-ion batteries and could halve the cost of energy storage for wind and solar generators.

Furthermore, Tiamat, a spin-off of the CNRS research center, plans to build a sodium-ion battery factory in France with an annual capacity of five gigawatt-hours. The initial investment of around 150 million euros will be done for a capacity of 0.7 gigawatt-hours to be completed by the end of 2025.

These developments highlight the growing confidence and momentum in the sodium-ion battery industry. As sodium-ion battery technology continues to advance and overcome challenges, it has the potential to disrupt the lithium-ion battery market.

Although Chinese manufacturers currently dominate sodium-ion battery production, European and American companies are striving to catch up by scaling up their operations and gaining cost competitiveness.

Conclusion

Finally, the race for sodium-ion batteries is gathering traction, fueled by the need for enduring and cost-effective alternatives to lithium-ion batteries. Sodium-ion batteries provide advantages in terms of availability, cost, and the possibility of scalability. Despite their lower energy density and restrictions, sodium-ion batteries have shown promise in specialized applications and could play an important role in the transition to electric vehicles and renewable energy storage.

FAQ Section

- Q: What are the advantages of sodium-ion batteries for electric vehicles (EVs) and energy storage?

- A: Sodium-ion batteries offer a lower cost per kilowatt-hour compared to lithium-ion batteries, making them an attractive option for EVs and energy storage applications. They are also considered to be very safe and can be produced at a very low cost for large storage systems.

- Q: How do sodium-ion batteries compare to lithium-ion batteries in terms of cost and performance for EVs?

- A: Sodium-ion batteries are estimated to cost one-third less than lithium-ion batteries, making them a more cost-effective option. While they have a lower energy density at the cell level, they are very safe and can be produced at a very low cost for large storage systems.

- Q: Are sodium-ion batteries suitable for electric cars?

- A: Sodium-ion batteries are considered suitable for electric cars, especially for applications where the focus is on cost per kilowatt-hour and service life, rather than gravimetric and volumetric energy density. However, their suitability for electric cars is still being evaluated.

- Q: What are the main challenges facing sodium-ion batteries for EVs?

- A: The main challenges include lower energy density compared to lithium-ion batteries, as well as the need for innovative manufacturing and recycling methods. Additionally, the weight of sodium metal, which is about three times heavier than lithium, adds to the battery weight, impacting the overall performance.

- Q: How do sodium-ion batteries contribute to the transition towards sustainable energy solutions?

- A: Sodium-ion batteries could alleviate concerns about the available supply of low-cost elements for battery production, contributing to sustainable energy solutions. Additionally, they offer the potential for longer-lasting and more affordable electric vehicles with longer driving ranges.